PUMPING SYSTEMS

- Industrial Process

- Flat Centrifuge Sanitary Pumps

- Sanitary Pumps Positive Displacement

- Municipal Services

- Vertical Turbine Pump Pumps Propeller

- Others

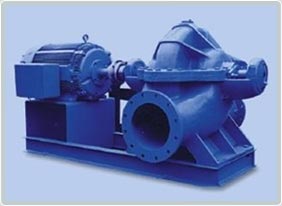

Municipal Services

Centrifuge

-

Manufactured following the Ansi B73 and API 610 norms, and in 1 ½ to 8 in size with the following materials:

- Gray iron.

- Bronze.

- Nodular iron.

- Stainless steels.

- CD4MCU with 25% chrome.

- High nickel iron.

Capacity of 50 to 4,000 gpm and dynamic charges from 40 to 300 ft. with semi-opened driver.

Moto-Pump

-

Direct coupling equipment with closed simple drivers of 10 to 250 gmp and dynamic shields of 60 to 150 ft. Two drivers of 30 to 350 gpm ans dynamic charges of 75 to 550 ft. Manufacturing materials:

- Gray iron.

- Bronze.

- Nodular iron.

- Stainless steels.

Vacuum Pump

-

Liquid ring vacuum pump with double driver and a 20 to 29 in. Hg vacuum. Rarefied air capacity of 600 to 1,00 pcm. Used materials:

- Gray iron.

- Bronze.

- Nodular iron.

- Alloyed steels S3000 & S4000

- Low-carbon steels

Vortex

-

Manufactured at sizes 3 to 6, flat and vertical with a 100% non-clogging driver for solid handling from 3" to 8" diameter. Materials:

It's manufacture is different metallurgy, like:

- Gray iron.

- Bronze.

- Nodular iron.

- Stainless steels.

- CD4MCU with 25% chrome.

300 to 3,500 gpm capacity with dynamic charges of 60 to 140 ft. It can be manufactured with mechanic seal and/or hydraulic seal.

Start Box Pump

-

Manufactured at sizes 3 to 6, flat and vertical with a 100% non-clogging driver for solid handling from 3" to 8" diameter.

It's manufacture is different metallurgy, like:

- Gray iron.

- Bronze.

- Nodular iron.

- Stainless steels.

- CD4MCU with 25% chrome.

300 to 3,500 gpm capacity with dynamic charges of 60 to 140 ft. It can be manufactured with mechanic seal and/or hydraulic seal.

Hydraulic Seal

-

Manufactured at sizes 1 ½ to 8", with a semi-opened and closed driver for 100 to 3,000 gpm performances and 30 to 250 ft. on dynamic charges. It works at 248° F temperatures.

- Gray iron.

- Bronze.

- Nodular iron.

- Alloyed steels S3000 - S4000 to 317.

- CD4MCU with 25% chrome.

Paper Pulp

-

Manufactured with a 4" and 6" discharge and an opened driver of 2 and 4 non-clogging blades. 500 to 2,500 gpm capacity and dynamic charges of 50 to 300 ft. Used materials:

- Gray iron.

- Bronze.

- Nodular iron.

- Stainless steels.

- CD4MCU with 25% chrome.

Centrifuge

-

Frontal suction with semi-opened and closed driver and 30 to 300 gpm capacity. Dynamic charges of 15 to 290 ft.

- Gray iron.

- Nodular iron.

- Stainless steels.

- Low-carbon steels.

Flat Non-Clogging

-

Manufactured with a 2-blend driver, 100% non-clogging, 10 to 3,000 gpm capacity and 25 to 575 ft. dynamic charge. Materials:

- Gray iron.

- Nodular iron.

- Stainless steels.

- Low-carbon steels.

web

mail Copyright © 2012 DYSAC All Rights Reserved.Privacy Statement